Electromagnetic Compatibility (EMC): what It is and how to ensure compliance in industrial environments

Electromagnetic Compatibility (EMC) is a critical factor for the safe and efficient operation of electronic devices in industrial environments. Without proper control of electromagnetic interference (EMI), machines and sensors may experience unexpected failures, affecting production and compromising operational safety.

In this article, we will explore the concept of EMC, the most common challenges, and how to ensure that your industrial equipment operates within the required standards.

What is Electromagnetic Compatibility (EMC)?

EMC refers to the ability of an electronic device to operate correctly in an electromagnetic environment without causing harmful interference to other equipment and without being affected by them.

It involves two key aspects:

- Electromagnetic emission – The equipment should not generate interference that affects nearby devices;

- Electromagnetic immunity or susceptibility – The equipment must function without failures, even when exposed to external interferences.

Compliance with EMC standards is essential to ensure the safety and reliability of electronic systems in sectors such as industrial automation, telecommunications, healthcare, and transportation.

Main EMC Challenges in the Industry

Industrial environments contain numerous sources of electromagnetic interference, such as electric motors, frequency inverters, transmission lines, and wireless communication networks. Some of the most common unwanted effects include:

- Operational failures – Nearby equipment may generate unwanted signals, known as “electrical noise,” which can interfere with the operation of sensors and controllers, causing measurement errors, display flickering, or unintended activations;

- Communication failures – Wireless networks and industrial protocols may suffer signal degradation due to external interferences;

- Resets or system crashes – Stronger electrical noise may cause unexpected device resets or even system crashes;

- Component damage – Electrostatic discharges (ESD) and electrical surges can damage sensitive devices, rendering equipment inoperable.

To minimize these issues, it is crucial to use certified equipment designed with filters and protection against interference.

How to Ensure Compliance with EMC Standards?

The best way to ensure that your electronic systems meet EMC requirements is to use tested and certified products according to related standards. Additionally, it is advisable to follow recommended installation, grounding, and shielding practices. Some effective strategies include:

- Shielded cables – Reduce electromagnetic interference in communication systems;

- Proper grounding – Prevents current loops that may introduce noise into the equipment;

- Transient suppression filters – Essential for eliminating voltage spikes that can affect electronic circuits;

- Choosing certified equipment – Products that comply with EMC standards ensure greater safety and operational reliability.

NOVUS and Electromagnetic Compatibility

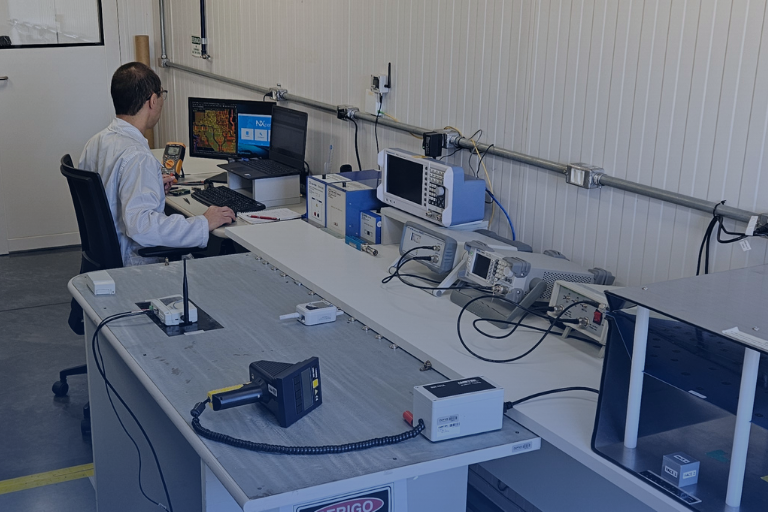

NOVUS develops electronic products following strict electromagnetic compatibility standards, ensuring that sensors, controllers, and data loggers operate without interference and comply with major market regulations, such as ANATEL (Brazil), FCC (United States), and CE Marking (Europe).

Our equipment is designed for demanding industrial environments, offering high immunity to noise and interference to ensure reliable and secure measurements.

Electromagnetic Compatibility is an essential factor for maintaining the efficiency and safety of electronic systems in the industry. Adopting best practices and selecting certified equipment helps prevent failures, improve productivity, and ensure compliance with regulatory requirements.

Want to learn more about how our products meet EMC standards?

Visit our website and discover NOVUS solutions for challenging industrial environments: https://www.novusautomation.com/site/