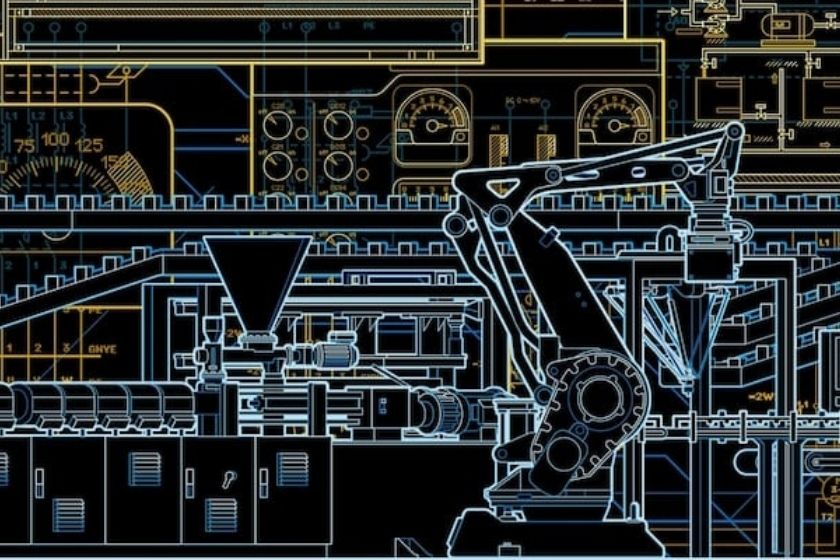

From industrial revolution to wireless connectivity: what is industrial automation?

NOVUS has been in the industrial automation segment for over 30 years developing solutions and products for several industries. However, the term “industrial automation” may bring doubts to people who are not familiar with the sector.

After all, what is industrial automation?

In a simple way, we can say that industrial automation is the optimization of industrial processes with automated systems, i.e., using technologies in specific processes to increase productivity and autonomy, improve working conditions and simplify some operations. With the automation of manufacturing processes and the consequent reduction of human effort, it is also possible to obtain more safety when performing tasks, eliminating or simplifying services considered dangerous.

Today, industrial automation is a concept intrinsically linked to Industry 4.0, which includes the Internet of Things and cloud computing in the pursuit of more intelligent factories. But long before the invention of the computer, people were already looking to improve factory efficiency.

From industrial revolution to wireless connectivity

Since the second half of the 18th century, society had been seeking advances in the automation field. In this period, the agrarian and artisanal production system was beginning to transform itself into an industrial one, especially in England. There, the first simple and semi-automated devices were developed. They also developed machines adapted to replace manual activities and increase production efficiency. The actions were controlled by mechanical parts, which “automated” the most repetitive work tasks.

Many technological advances occurred during the so-called First Industrial Revolution, such as the replacement of hydraulic power with steam power. In the first half of the 19th century, there were telegraphs, the first initiatives in the field of electricity, and the advance of the textile industry and metallurgical industry. However, it was not until after the Second World War, in the 20th century, that the first numerical control machines and process control systems emerged. At this time, analog integrated circuits were also created and resulted in a new generation of automated systems.

In the 1970s, the first computers were used to control large automation systems. However, due to the high cost of maintenance and the difficulty of programming these machines, they were replaced by Programmable Logic Controllers, much more advanced devices that were developed especially for industrial processes.

In the 1990s, technology already allowed for circuits and computers with high processing power, which generated more efficient, faster, and more reliable automation systems. This allowed for larger scale production with reduced costs, optimization of spaces, increased reliability and technical safety.

Thus, we have reached the first half of the 21st century, where automation is part of our daily life, even inside our homes, as we have sensors to control the air conditioning temperature, alarm clocks set to ring at predetermined times, and a myriad of intelligent and increasingly connected devices.

Industrial automation today

Computers are the basis of modern industrial automation. The networks used in industry are the result of the need for communication between different equipment and systems. Today, automation relies on cyber-physical systems that control material processes and manage decision-making in a decentralized manner.

With the creation of the IoT, these systems can “talk” to several machines simultaneously and send information in real time to managers and supervisors. However, simpler electrical and mechanical systems continue to be used in many industries as they have a lower implementation cost and there are still processes where manual labor is critical to product quality.

There are 6 principles that are the focus of industrial automation today:

- Interoperability: The ability of systems, machines, assembly stations, products, and humans to communicate with each other through the Internet of Things and Cloud Computing.

- Virtualization: Interconnected data sensors create simulations of the industrial environment and make it possible to remotely track and monitor all processes.

- Decentralization: With the systems, machines do not need human intervention to make decisions that meet production needs.

- Real-Time Capability: Instantaneous data download and analysis.

- Service-Orientation: Makes services (of systems or humans) available through cloud computing.

- Modularity: Ability to adapt production flexibly and according to the expansion, replacement, withdrawal, or modification of modules.

Within industrial automation there are 3 areas, responsible for ensuring that the principles work together: electronics (hardware architecture and implementation), mechanics (actuating devices), and information technology (system control software).

Automation systems need communication networks to ensure speed and, especially, security during the exchange of data between sensors, controllers, and other devices involved in the process. The networks are also essential for field equipment because they allow to manage information in dangerous or difficult to access regions. From a control center connected to the network, the supervision team can get an overview of the system at any time and place, being able to make decisions at the appropriate time.

Conclusion: increasingly automated factories and benefits on many fronts

Process automation in industries has several benefits. First, there is the maintenance of the quality standard: experts in quality standards are certain that automated systems result in greater excellence, as the machines are designed not to fail and to work to rigorous standards.

Automation also allows the factory to work with a focus on zero waste, which saves energy, human labor, and raw material resources and makes better use of residues.

Automated systems make the production capacity of industrial processes more adaptable and allow changes in manufacturing parameters and product specifications. In addition, they provide more precision and technical safety, ensuring that complex, unhealthy, or hazardous operations, which could never be performed by manual methods, are carried out.

We know that the industrial sector is very demanding regarding internal and external processes, and industrial automation makes it possible to better organize the company and bring more security to the production line. The automation professionals must also adapt and be in constant evolution because the factories’ automation can create new demands. In the past, automation replaced repetitive manual processes. Nowadays, more and more technical areas also enjoy the benefits of automation.

Industrial automation is a reality in almost all industry segments, as all areas seek to improve processes, results, quality, and efficiency. What does your company need to obtain ever better results with the help of automated systems? Talk to our specialists: NOVUS always has a solution to exceed your expectations and achieve your goals.