Efficiency when managing assets with real-time monitoring

While the focus of innovation in the sector in recent years has mostly been on the energy generation process, the distribution stage already has many smart and connected opportunities to improve efficiency. The current demand for sustainability highlights the need to monitor the network and utilities assets.

Reducing losses is extremely important when it comes to ensuring the rational functioning of the supply chain. Modernizing the energy sector is an urgent necessity and this task is at the top of the priorities for the managers of energy distributors. When we expand our focus, we realize that it is also a concern for input manufacturers, such as transformers.

If industry is already achieving new productivity standards with IoT, the digitalization in the electric power industry is capable of modernizing processes by making the entire utilities sector more efficient. The constant and detailed monitoring of the main indicators of energy systems is the main activity that benefits from digitalization, but the benefits have a positive impact on all areas of the operation.

IoT for energy monitoring

The technological revolution that has begun with the Internet of Things (IoT) makes it possible to carry out intelligent, low-consumption measurements using signals that indicate the efficiency and operating conditions of equipment.

Technological development focused on the energy sector mainly makes it possible to:

- Ensure the safety of employees and consumers by preventing short circuits and explosions.

- Reduce energy supply interruptions.

- Optimize maintenance, preventing failures and reducing downtime.

- Minimize the premature replacement of assets, helping to extend the lifespan of equipment.

- Boost team performance, making them more efficient and productive.

- Reduce operating costs, maximizing return on investment.

Driven mainly by the search for a more efficient electric grid, application context connectivity can promote better services and experiences for consumers while providing optimized management at utilities and distributors.

Technology for energy distribution

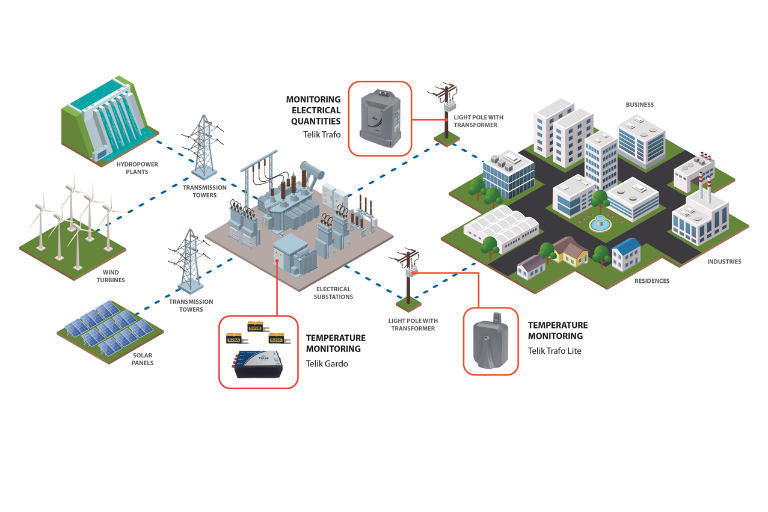

A reference in the electronics industry, Brazil’s NOVUS Automation has distinguished itself by presenting specialized solutions. In the energy sector, the Telik line innovates with products that provide relevant data when monitoring transformers. This line is scalable and highly mobile, easy to install and cost-effective for this application.

By monitoring the temperature, Telik Trafo Lite can keep track of the transformer’s performance. In addition to being able to analyze the behavior of the asset during the supervision time, it is possible to verify that the device is in the correct operating state, which helps to identify any need for intervention in advance.

The connection is external, made when the equipment is magnetically attached to the transformer. One of the magnets is the temperature sensor itself. It is the LoRA technology contained in the device that makes it possible to transmit data over a long range and with low power consumption. In addition, the device has a battery that can operate for around 10 years.

Meanwhile, Telik Trafo, a solution for low-voltage networks, is an energy meter used to analyze the balance and load of transformers and perform comparative and inspection measurements. With a robust appearance for use outdoors, it can access data on site (via Wi-Fi) or remotely (via the 4G Mobile Network, fallbacking to lower technologies when necessary). It not only measures all the electrical quantities derived from voltage and current, but also has the Last Gasp feature, which allows it to immediately report a power failure.

In electrical panel busbars, restricted areas that are difficult to extract information from, Telik Gardo is the perfect device to monitor the integrity of the process. It doesn’t need a battery or wired power. As well as being easy to install due to the absence of cabling, the fact that temperature sensors don’t need a battery means they can provide greater visibility of essential information and ensure fast decision-making.

Read too

The development of Telik Trafo Lite

How NOVUS products are tested during development

Data logger in weather stations: Bulbe Energia uses FieldLogger in more than 30 photovoltaic plants