Custom Linearization versus Custom Calibration

NOVUS Automation has 2 methods for adapting the signal read from the equipment to the ideal response expected by the user: 1) Custom linearization and 2) Custom calibration. These methods are present in some NOVUS products. But what is the purpose of each and what is the difference between them?

Custom Linearization

Custom linearization is present, for example, in the N1500 and N1540 indicators. It allows to apply a linear transformation to an input signal. The aim of this signal is to generate a signal which, in turn, represents the quantity of interest in a more intelligible way.

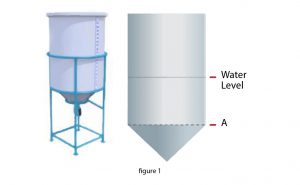

A typical example: Receiving a 4-20 mA signal from a level transmitter in a tank with a conical bottom and adapting this signal to indicate the volume of water in the tank. Figure 1 shows that the volume has a correlation with the level signal, which changes from point A onwards.

With custom linearization, points are inserted in the equipment. These points create line segments to conform the input signal to the expected output. This way, the change in behavior from point A can be “compensated” so that the indicated volume always shows the correct value.

Custom Calibration

Custom calibration is applied to correct differences between the indicated value and the value we expected to be indicated. Currently present in FieldLogger and in some products under development, it also works through pairs of points with the value indicated and the value it should indicate. These, in turn, create line segments with the function of adjusting the display. It is a very useful feature in calibrations and adjustments made by laboratories.

It’s worth highlighting that the indication correction doesn’t just occur at the inserted points, but throughout the entire indication range. For example, if the user measures 100.8 °C instead of 100.0 °C, as expected, and enters this pair of points in the custom calibration, the device will indicate 100.0 °C whenever it is measuring 100.8 °C. This -0.8 °C compensation spreads across the range, its effect diminishing as you move away from 100 °C.

Although they were designed to solve different problems, the two methods are implemented in a similar way, which sometimes makes it possible to use one instead of the other. However, each of them has the necessary features to solve a particular type of problem. Knowing exactly what the problem is makes it possible to make the best use of these resources.

In addition to Custom Linearization and Custom Calibration, NOVUS products typically have a user Offset parameter, allowing the user to shift the measurement/indication in a configurable level. In these cases, the set offset is valid for the entire measuring range.

[robeta e tl400]

Read too:

How the TL400 level sensor was developed

Level measurement in industrial processes: New solutions to complex challenges

Data logger: What is it, who uses it, and how to calibrate it